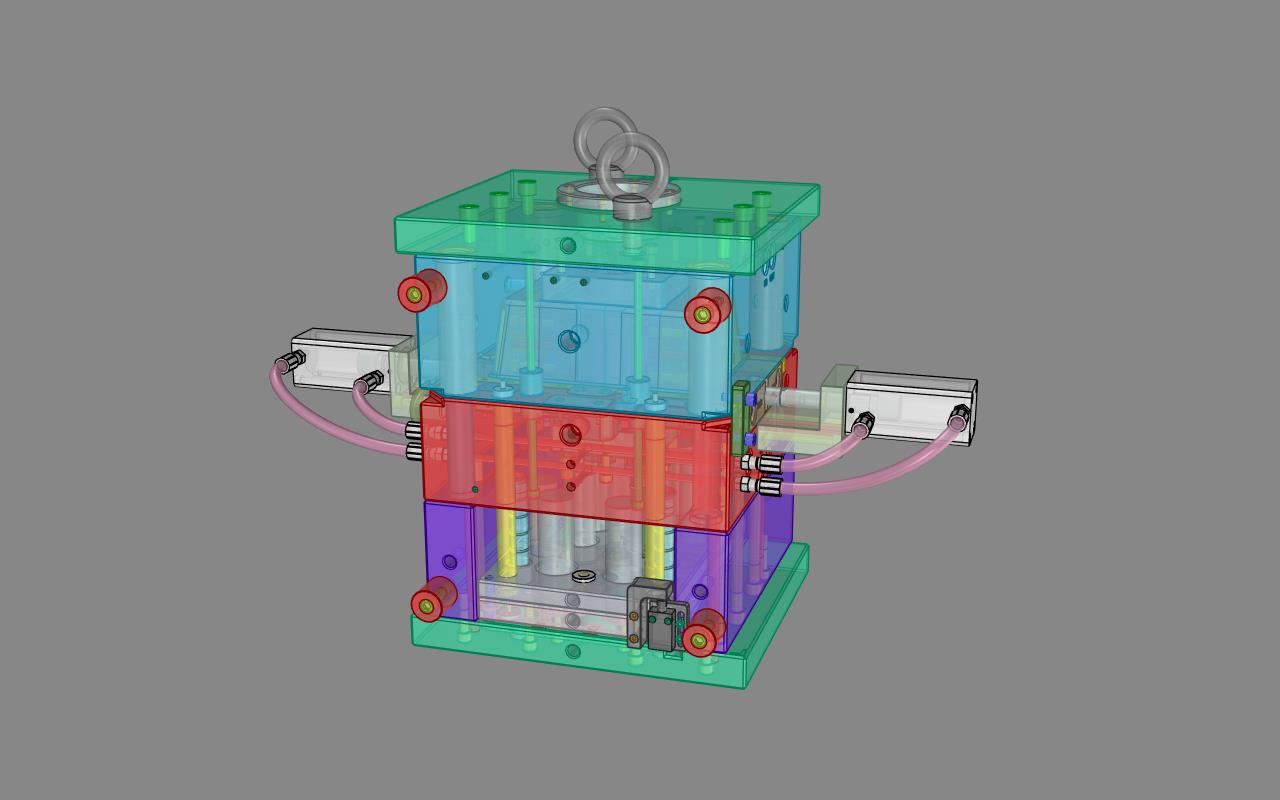

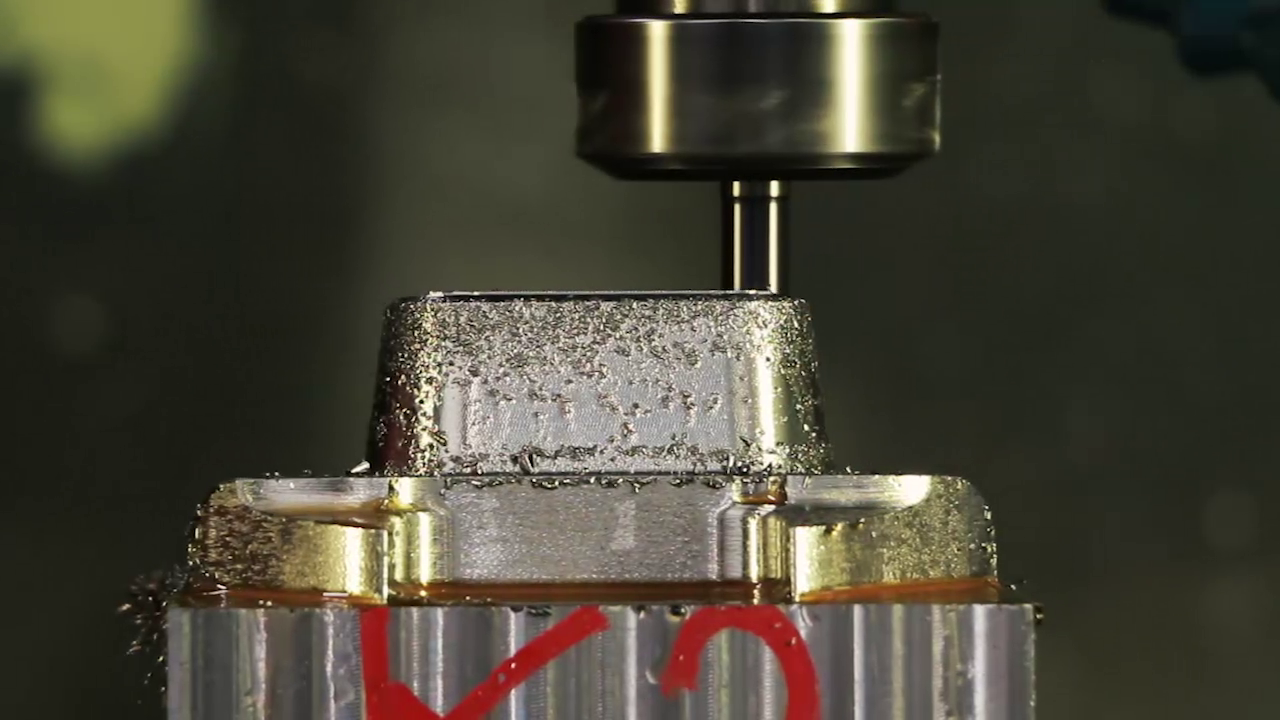

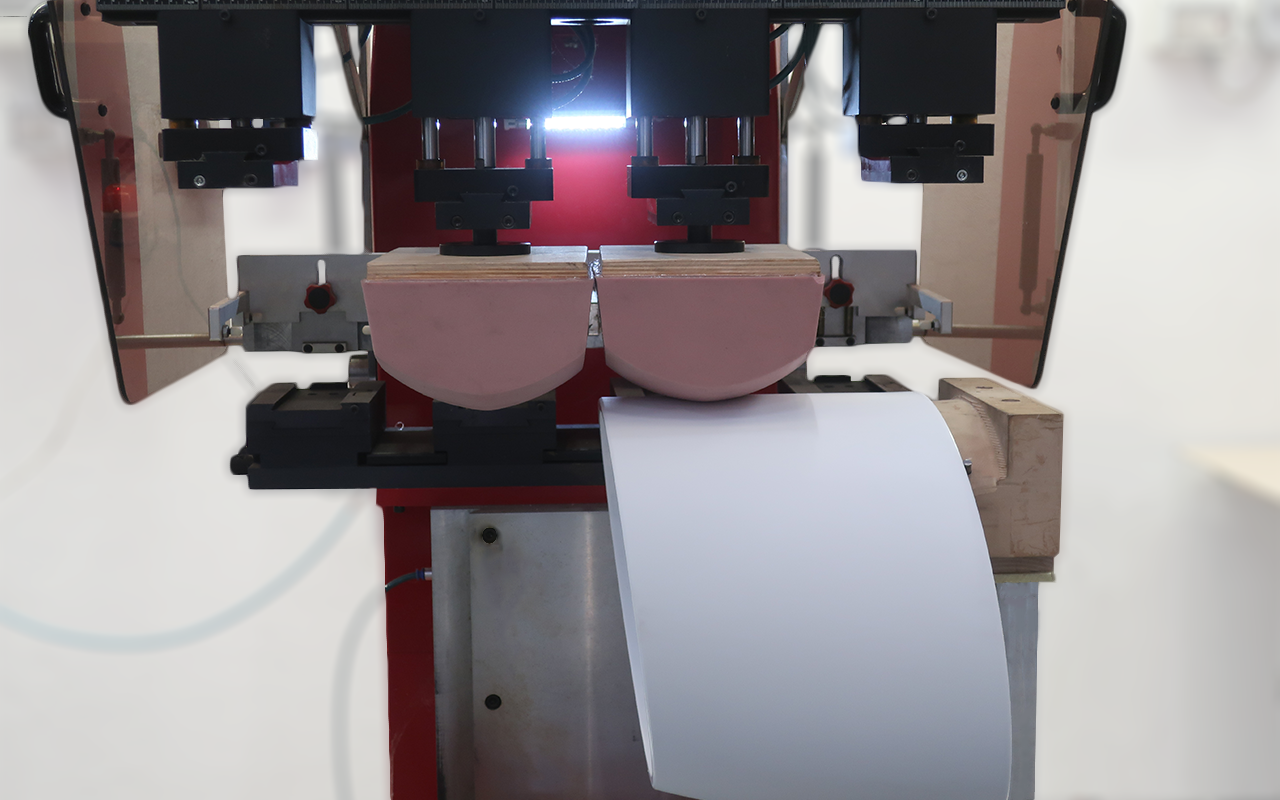

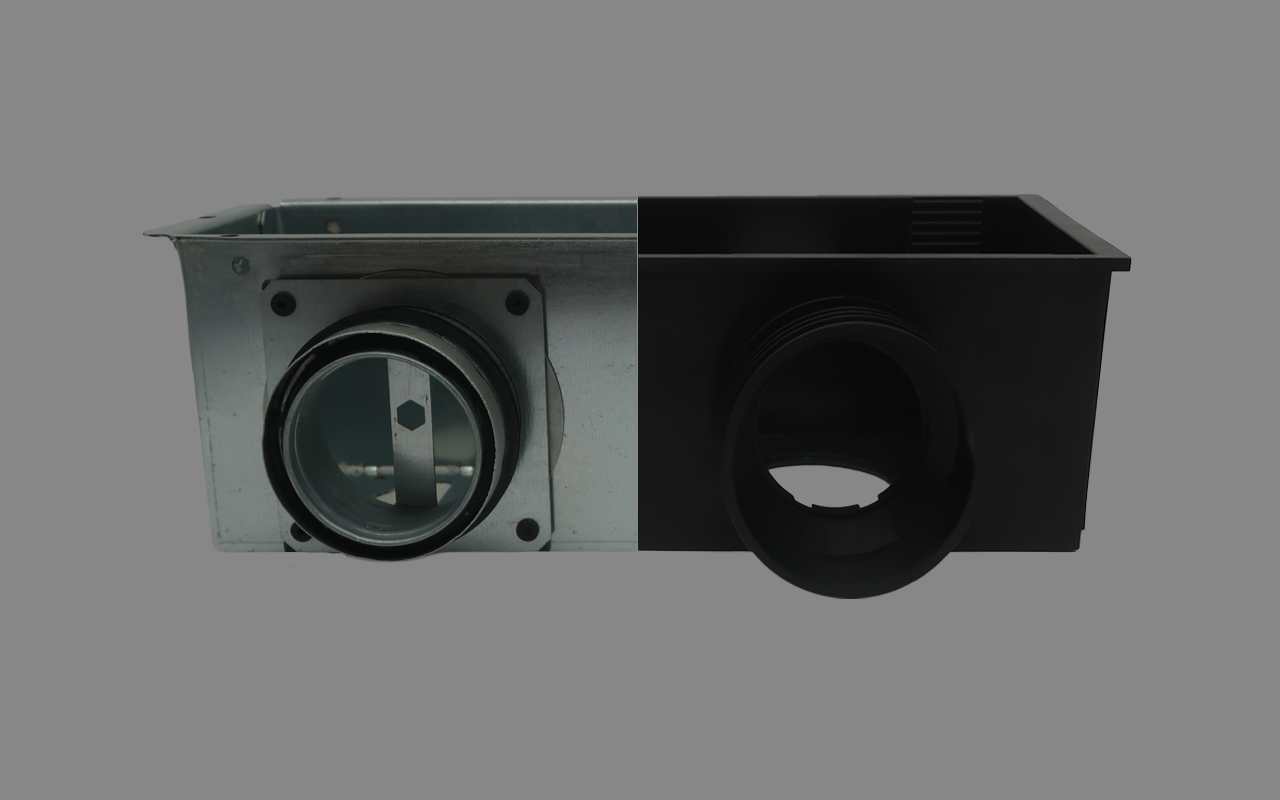

Engineering and co-design

We support customer from the early development of the design, engineering and choice of the most suitable plastic raw material in order to integrate customer needs with the characteristic of injection moulding process. Thanks to our experience and know-how in mould making and plastic injection moulding production, we become a patner of our customer to obtain a finished product which satisfy all needs for which it was designed.